Track and Trace Solutions for Electronics Manufacturing in India

- Tack Innovations

- Jan 20

- 4 min read

A smartphone motherboard contains 200+ components from 15 suppliers across 8 countries. Without proper tracking, one counterfeit chip or assembly error can trigger massive recalls costing electronics manufacturers millions in losses and reputation damage.

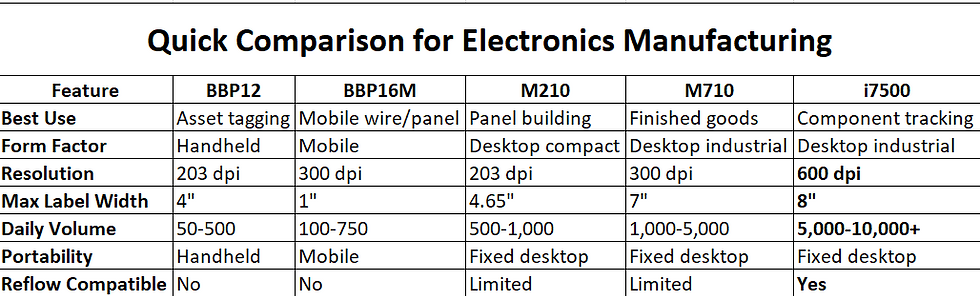

This guide covers why track and trace is essential for electronics manufacturing, how barcode label printing machines enable component traceability in traceability-critical environments, and which BRADY thermal printers work best for different applications.

The Importance of Track and Trace in Electronics Assembly

Component-Level Traceability

Electronics products contain 50-500+ components per assembly. When a capacitor batch fails quality testing, manufacturers need to identify which finished products contain those capacitors. Without component-level tracking, entire production runs may need recall. With barcode labels, manufacturers isolate affected units within hours instead of weeks.

Regulatory Compliance

India's electronics manufacturers face strict compliance requirements. RoHS compliance restricts hazardous substances and requires tracking material composition through the supply chain. Track and trace systems generate required records automatically through barcode scanning at each stage of EMS production.

Counterfeit Prevention and Quality Control

Unique serial numbers on barcode labels verify authentic components and prevent grey market diversion. Production data analysis reduces defect rates by identifying patterns at specific workstations on SMT lines.

Barcode Label Printing Requirements for Electronics Assembly

Consumer-grade printers cannot meet electronics industry requirements for precision, durability, and system integration in traceability-critical environments.

High-Resolution Printing

Small components measuring 0.5cm x 0.5cm require 300-600 dpi resolution. DataMatrix 2D codes store more data in smaller space than 1D barcodes but require high-precision printing. Print quality must ensure 100% scan rate at automated inspection stations. When barcode scanners fail to read labels, SMT lines stop.

Small Label Capability and Durability

PCB components need labels as small as 0.25" x 0.5". Thermal transfer printing ensures labels survive reflow soldering temperatures up to 260°C. Labels must withstand flux cleaning chemicals, handling during assembly, and quality inspection while remaining scannable through the entire production process.

MES Integration

Label printing machines must connect to Manufacturing Execution Systems (MES) for real-time data printing. Variable data includes serial numbers, date codes, and component IDs that change with every label. Automated SMT lines need this integration to operate with minimal manual intervention.

BRADY Thermal Printers for Electronics Industry

BRADY industrial label printers create durable barcode labels that survive electronics manufacturing processes across EMS production and panel building operations.

BRADY i7500 Industrial Label Printer

The i7500 is a high-resolution thermal transfer printer for electronics component tracking on SMT lines, providing 600 dpi precision for demanding applications.

Key Features:

600 dpi resolution prints tiny DataMatrix codes on labels as small as 5mm x 5mm for ultra-small IC chips and micro-components

Print speed of 14 ips keeps pace with high-speed SMT assembly lines

Zero wastage die-cut label printing, eliminates material waste between labels

Temperature-resistant polyimide labels survive reflow soldering at 260°C

ESD-safe design with grounded chassis prevents static discharge

MES integration via Ethernet for real-time data printing

Applications: Component-level serialization for smartphones, PCB assembly tracking with 2D codes, semiconductor identification, micro-component labelling, and high-mix production with frequent label changes.

BRADY M710 Label Printer

The M710 handles medium-volume production with 300 dpi resolution suitable for larger labels in EMS production facilities. Best used for finished goods labelling and export compliance.

Key Features:

Print speed of 10 ips handles 1,000+ labels per shift

Label width up to 7 inches for shipping cartons and pallets

Network connectivity integrates with ERP and WMS systems

GS1-128 barcodes support export compliance

Applications: Finished product serialization (TVs, laptops, appliances), shipping carton labels with RoHS compliance information, warehouse inventory management, and export documentation.

BRADY M210 Label Printer

The M210 offers compact industrial performance for facilities with moderate labelling needs. Best used for small to medium EMS production facilities and panel building operations.

Key Features:

Compact footprint fits in space-constrained production areas

203 dpi resolution handles standard component and wire labels

Print speed of 4 ips for operations printing 500-1,000 labels daily

USB and Ethernet connectivity for basic MES integration

Handles labels up to 4.65 inches wide

Applications: Wire and cable identification for panel building, component bin labels, work order tracking, small batch production labelling, and quality control inspection labels. The M210 bridges the gap between portable printers and high-volume industrial models.

BRADY BBP12 Portable Label Printer

Key Features:

Handheld design with battery operation

Touchscreen interface requires no computer

Wi-Fi connectivity for cloud-based systems

Quick label changes for different sizes

Applications: SMT machine asset tagging, maintenance schedule labels, prototype and R&D component labelling, test equipment calibration labels, and panel building equipment identification.

BRADY BBP16M Mobile Label Printer

Key Features:

Mobile design with rechargeable battery for all-day operation

Prints labels up to 1 inch wide with 300 dpi resolution

Colour touchscreen with intuitive label design interface

Wi-Fi and Bluetooth connectivity for wireless printing

Magnetic back and built-in handle for one-handed operation

Applications: Production floor wire labelling for panel building, temporary production labels during prototype runs, field service equipment tagging, inspection and test labels on SMT lines, and on-demand component identification.

Tack Innovations: Your Partner for Electronics Manufacturing Labelling

As an authorized BRADY distributor, Tack Innovations understands the unique challenges of electronics manufacturing in India. Our specialized capabilities for the electronics industry include:

Ability to print on ultra-small stickers (5mm x 5mm): Perfect for micro-components, IC chips, and SMD parts where space is extremely limited. The BRADY i7500 with 600 dpi resolution ensures scannable DataMatrix codes even on the smallest electronic components.

Zero wastage label printing: Die-cut label technology eliminates material waste between labels, reducing your operational costs and supporting sustainable manufacturing practices. Critical for high-volume electronics production where label costs add up quickly.

These capabilities, combined with BRADY's industrial-grade thermal transfer technology, ensure your electronics manufacturing facility achieves complete component traceability without compromising efficiency or increasing waste.

Implement Track and Trace in Your Electronics Manufacturing Facility

Choosing the right label printing machine is critical. High-resolution printing for small components on SMT lines requires industrial-grade thermal transfer printers, while panel building operations need durable wire and cable labels.

Investing in proper barcode label printing machines prevents costly recalls, ensures export compliance, and builds customer confidence in product quality across EMS production operations.

Need barcode label printing machines for your electronics manufacturing facility?

Tack Innovations is an authorized BRADY distributor in India. Request a quote for i7500, M710, M210, BBP16M, or BBP12 printers with technical support included.

Comments